Technical brief

18 Nuts for above (16)

19 Enamel paint black matt

20 Double sides reparering tapes

Total

260 Nos

2L

50 m

2.50

570

200m

650.00

1,140.00

6600.00

301680.00

The Fabrication Process

Stationery Solar Powered Fish Dryer

The following step by step process is recommended for the

construction of the stationery solar powered fish dryer:

• Selection of the site – Avoid marshy, muddy lands.

Sandy soil is best. The area needs to be levelled and

have a proper drainage system. The area should have

direct sunlight (unhindered by trees etc.) The dryer

needs to be expos ed to sunlight from 9.30a.m to 3.30

p.m to work efficiently.

• Select suitable workers - Call for offers from

prospective artisans for fabrication of drier as per

detailed working drawings. The skills of the artisans

and the construction workers need to be assessed in

the selection process.

• Clear and prepare site area - An area of at least twice

the length and breadth of the dryer’s structure should

be cleared of scrub jungle.

• Excavate ditches to lay foundation - The soil should be

excavated as per B.O.Q submitted for civil works.

• Erect the foundation walls, and timber columns in place

as per B.O.Q.

• Prepare floor – Fill and ram the earth, adding water as

required to compact the earth firmly and level the area.

• Construct half walls and fix chimneys- The chimneys

need to be incorporated into theside walls and thus

should be constructed simultaneously. The chimneys

need to be fixed with inlet air ducts and roof ventilators.

Next the rodent guard needs to be put in place right

round the 2.5 ft half brick wal level. Plaster and

smoothen both sides of the brick walls. Apply matt

black paint on the exterior walls and outer side of the

chimneys.

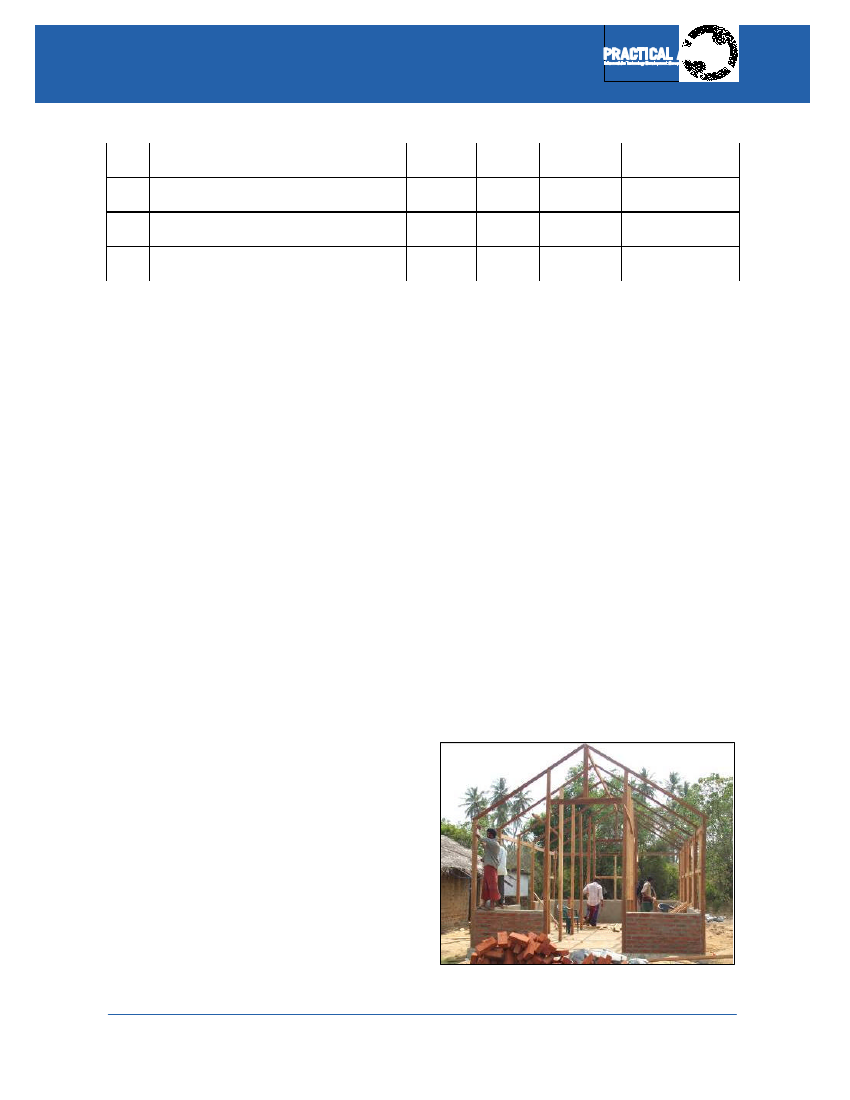

• Construct timber super structure – this serves as the

framework for the upper walls and roof.

• Place the matt black coated metal collector plates on

the support framework, making adequate provision for

space between any two plates.

• Erect and fix framework

• Construct half walls and fix chimneys- The chimneys

need to be incorporated into the side walls and thus

should be contructed simulataneously. The chimneys

need to be fixed with, inlet air ducts and roof

ventilators. The in place. Next the rodent guard need to

be put inplace right round the 2.5 ft half brick wall level.

Plaster and smoothen both sides of the brick walls.

Apply matt black paint on the exterior walls and outer

side of the chimneys.

Practical ActionConstruction and maintenances of solar fish drier Technical brief

10